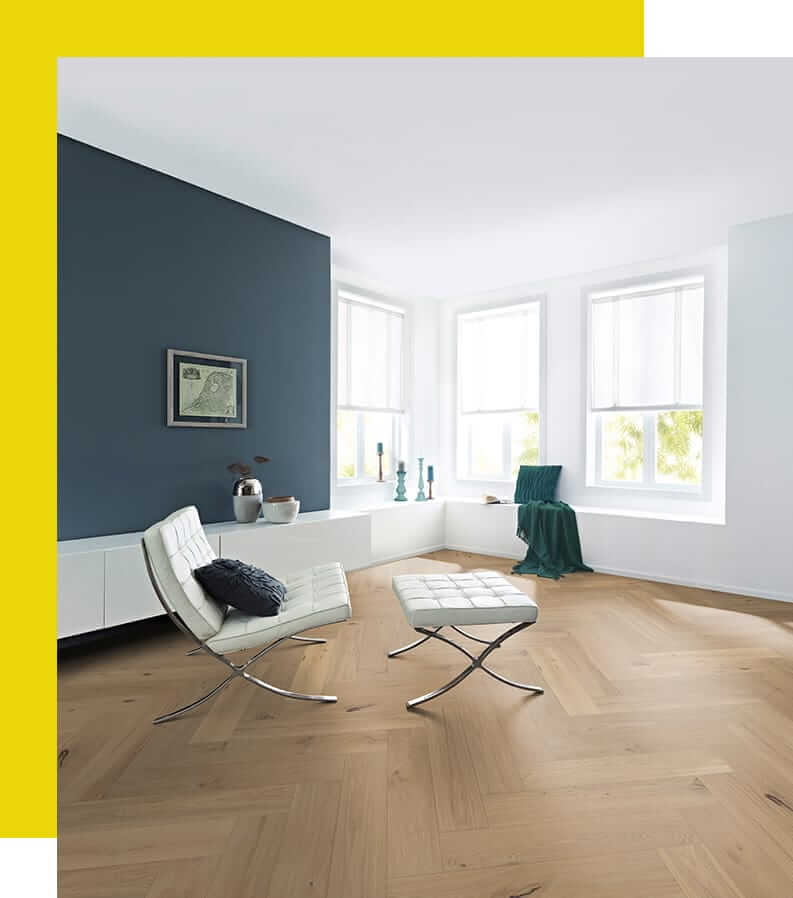

A wooden floor or parquet flooring is made of solid wood top layer thickness not less than 2.5 mm before installation.

Lived and treated with due diligence and protected by its paint, the parquet can be very durable. To avoid, for certain, is the aggression of external agents that can scratch the surface of the floor, like heels, nails of pets, contact with pointed objects, etc.

When it comes to floor heating, the choice of wood is the optimal one because the parquet, insulating material by nature, prevents direct contact with the heat emitted by the radiant panels. All pre-finishes are suitable for laying on under floor heating systems, as they are equipped with a multilayer support engraved in several parts, therefore allowing to spread the heat homogeneously across the surface. By the way, the normative reference is the same and generally the heating system is also the same one that cools. However, it is to be added that the technologies of these systems are constantly evolving. Particular attention should therefore be paid to the floor-to-floor heating system design. It is important to ensure that the system is pressurized to overcome any problem in the coil and implement the pre-cycle of heating / cooling before laying.

The wooden floor can be safely laid in both the kitchen and the bathroom. Water, in fact, if not stagnant, does not damage the parquet. What’s useful, then, is choosing more stable wood species in contact with humidity, such as Doussiè, Merbau, Iroko and Teak. The oak requires some caution, because in contact with moisture it tends to create black spots caused by the spillage of tannins, very present in this wood species. It is advisable, for good floor care, to always open the windows and aerate the premises after using showers or the like to eliminate any moisture that has been deposited inside the rooms and prevent that this alters the floors.

Yes, if the floors like tiles, ceramics, stone, marble, and derivatives are solidly fixed. Carpet, PVC and linoleum are incompatible with the laying of parquet: these, with any trace of the old glue should be removed from the foundation. On a ceramic floor it is first necessary to remove any residual wax, dirt or grease deposited over time, then the ceramic should be sanded, in order to make the glue more intense.

Dimensional stability is indicative of changes in the volume of the wood at varying humidity and room temperature. Dimensional stability is calculated by applying the test method established by UNI EN 1910.

Wood hardness is the property of wood that indicates its resistance to penetration. It is determined by following the procedures and the instructions imposed by UNI EN 1534 – Determination of penetration resistance (Brinell). Brinell hardness is determined by the size of the cargo impression found in the wood. The smaller the size of the imprint, the greater the hardness of the wood, and so the harder and more durable the floor. It is important to consider that wood is a living material and its structure, shaped by nature over the years, is not uniform: for this reason, the Brinell test is performed several times on every wood essence.

Outdoor decking is a strip of solid wood suitable to be installed in outdoor environments. The material is supplied with or without non-slip knurling in the upper part and with the notches for the insertion of the clips, which guarantee the sealing at the topside / strip below and create a space between the staves of about 3/4 mm necessary for the water drain to the ground. The floor exterior is accompanied by oil for the treatment and maintenance of equipment (against the graying due to weathering and ultraviolet solar and lunar rays). For a good floor maintenance, this treatment must be renewed annually after the winter season after washing with the cleaner. In addition to the outdoor decking planks with clips to attach, tiles are pre-composed with solid wood top and bottom with plastic support. The tiles are practical and quick execution of the pose running or chess.

Non experienced production has in most cases only one advantage: lower costs. On the other hand it has a huge disadvantage: the non-traceability of the product. We are not able to know the materials in the product and their origin, such as glues and paints. The impossibility of knowing the quality of raw materials and components make these products unreliable and potentially harmful to your health. This results in a failure to protect the final consumer.

The decision is completely subjective, but there are some characteristics related to the two types of flooring that can help you choose. The underlayment has a shorter shutter speed, it is walk able after just 24 hours, but after the massive installation must be sanded and finished on site (an advantage when you request a custom finish, detail) operations which take about thirty days . The prefinished has a greater dimensional stability; due to the phenolic birch, plywood and you may have maximum sizes higher than in the solid. The underlayment is also recommended for installation on heated screeds and / or cooling in the floor and in the event of restructuring of existing floors, places where the laying of the massif could give you some problems if you do not take the right precautions. Those who want to recreate an environment characterized by an antique flavor, choosing a completely natural material (no glue, 100% noble wood), require the massive.

Melamine and laminate floors are very different from hardwood floors. They are a kind of decorative coating that, by exploiting the existence of melamine resins applied on their surface, look like wood and floors but have nothing to do with the characteristics of naturalness, warmth and quality of the first ones. They are built with support materials derived from wood, such as chipboard, MDF or HDF, that are very sensitive to variations in humidity.